Have you ever drooled over a concept car with cool custom carbon fiber bits? Well, it might be time to dive into a carbon fiber wrap project—and take your handiwork to the next level.

Carbon fiber is a remarkable material. Race car builders and customers love it for its combination of light weight, high strength, and visual appeal. If you’ve worked with fiberglass resin and cloth in the past, you might have an idea of what a CF wrap project entails.

While you can find fiberglass cloth and resin at any auto parts or home improvement store, that’s not the case with carbon fiber material. You need to buy the products from a specialized merchant. To be clear, we’re talking real-deal DIY carbon, not pseudo carbon vinyl wraps.

Fortunately, Composite Envisions of Wausau, Wisc. offers a broad range of carbon fiber, Kevlar, and advanced weaves—along with epoxies, polyester resins, and a host of supplies for vacuum bagging, infusion, and mold-making on their Elite Motoring eBay Store.

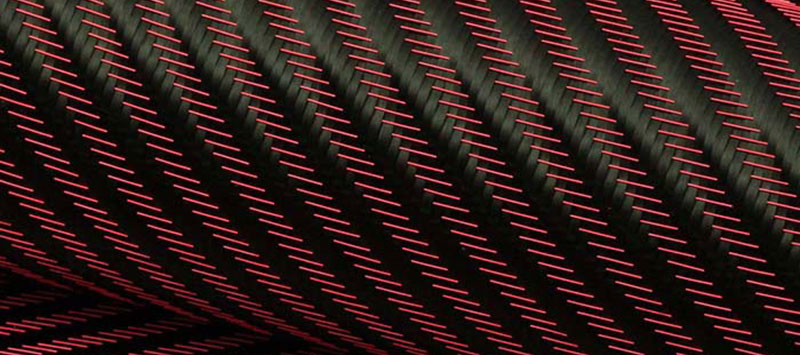

Composite Envisions has helped thousands of folks get their projects wrapped. In fact, Nissan called on Composite Envisions to supply its red Reflections 2×2 Twill carbon fiber fabric for the Infiniti Eau Rouge concept vehicle, which was revealed at the 2014 North American International Auto Show in Detroit. The exquisite Eau Rouge interior features carbon fiber panels that sweep from the center console up to the center stack, along with door panel inserts for a stunning effect.

Start Slow

Concept cars like the Eau Rouge inspire folks to do daring things, but you’ll do well to start out slow. It’s best to begin your foray into the world of carbon fiber wrapping with a basic shape. An inexpensive cell phone case is an idea first project.

“A lot of our customers start out by wrapping simple parts such as trim pieces in their vehicle,” said Cory Thorson, president of Composite Envisions. “The parts are usually cheap to replace if they get messed up on the first try. They are usually a simple shape which is easy to wrap, and the smaller size makes the project less daunting.”

A simple wrap might only require one layer of cloth—although the base object should be a similar hue to avoid showing through. A number of layers of epoxy or resin will also be applied and sanded.

Carbon-fiber wrapping process steps:

- Cut the cloth to size.

- Affix the cloth to the base object with a spray adhesive.

- Permeate the cloth with epoxy or polyester resin by brushing it onto the cloth.

- Repeat and sand as necessary.

- Finish with multiple layers of clear coat for the deepest, wettest look.

Achieving a smooth bubble-free finish is the big trick. “Using multiple thinner layers of epoxy and a heat gun to pop bubbles usually works pretty well,” said Thorson. “You can use a vacuum system to aid in better finish quality, but that is generally used when you have a little more experience.”

There are three basic types of materials:

Carbon fiber: Extremely strong and easy to sand and cut, but will quickly dull blades. It’s able to take a lot of abuse, but when it fails, it fails completely.

Kevlar: Very strong and abrasion resistant, but is tough to cut and sand. This makes it difficult to achieve nice edges. When Kevlar parts fail, the yarns usually hold parts together to keep it from complete failure.

Fiberglass: Cheap and easy to work but requires more layers of material and resin to achieve the same strength as carbon fiber. This results in a much heavier part.

Ready to get rolling? “You might mess up a few times at first,” said Thorson. “Videos and tutorials are good, but the best way to figure it out is to just get started.”

See Carbon Fiber Kit for sale on eBay.